- Home Page

- Company Profile

-

Our Products

- Microscope

- CONFOCAL MICROSCOPES

- Trinocular Upright Metallurgical Microscope

- Portable Grooved Metallurgical Microscope

- Cell Culture Imaging System

- Metallurgical Microscope

- Projection Microscope

- Student Stereo Microscope

- BINOCULAR STEREO ZOOM MICROSCOPE

- PCB Inspection Video Stereoscope Microscope

- SPINNERET MICROSCOPE

- Penta Head Microscope/ Multi view Head Microscope

- Research Polarising Microscope

- Senior Dissecting Microscope

- Dissecting Microscope

- Motorized Comparision Microscope

- Sieves Digital Microscopes

- Advance Inverted Tissue Culture Microscope

- Advance Stereo Zoom Microscope

- Student Projection Microscope

- Inverted Metallurgical Microscope

- Measuring Microscope

- Digital Spinneret Inspection Microscope

- Portable Inverted Tissue Culture Microscope

- Binocular Inverted Tissue Culture Microscope

- Student Compound Microscope

- Trinocular Stereozoom Microscope

- Advanced Research Microscope

- Gemological Microscope

- Polarizing Projection Microscope

- Senior Inspection Spinneretscope

- Confocal Microscope

- Senior Projection Microscope

- Toolmaker's Microscope

- Research Microscope

- Stereo Inspection Microscope

- Student Medical Microscope

- Digital Biological Microscope RXLr-4D

- Toolmaker Microscope Large

- Stereo Inspection Scope

- Trinocular Research Microscope

- Portable Metallurgical Microscope

- Binocular Research Microscope

- Student School Microscope

- Inverted Tissue Culture Microscope

- Projection Microscope

- Laboratory Microscope

- Decca Head Microscope

- Advanced Research Material Microscope

- Microtomes

- Semi Automatic Rotary Microtome

- Senior Precision Rotary Microtome

- Rocking Microtome

- Rotary Microtome Erma Type

- Freezing Microtome

- Fully Automatic Rotary Microtome

- Manual Rotary Microtome RMT-25

- Advance Rotary Microtome

- Hand Table Microtome

- Knife Sharpener Microtome

- Sliding Miocrotome

- Slide Staining Machine

- Rotary Microtome

- CRYOSTAT MICROTOME

- Optical Instruments

- Tissue Processor Machine

- Microscope Accessories

- Histopathological Equipment

- Lab Instrument

- Radical Digital Turbidity Meter

- Radical Microprocessor Dissolved Oxygen Meter

- Digital Photo Colorimeter

- Tap Density Tester

- Serological Water Bath

- Magnetic Stirrer

- Dual Channel Flame Photometer

- pH or mv or Conductivity

- Round Centrifuge

- Radical Disintegration Test Apparatus

- Digital Slide Scanner

- Precision Water Bath

- Incubator Shaker Water Bath

- Hemoglobin meter

- Microprocessor Colony Counter

- PASS BOX DYNAMIC

- Radical Microprocessor Colony Counter

- Bulk Density Apparatus

- Laboratory Rectangular Hot Plates

- Tablet Dissolution Test Apparatus

- Hemoglobin Meter (Sahli's)

- Micro Centrifuge 16000 R.P.M.

- Revolutionary General Purpose Digital Centrifuge

- Vortex Shaker

- Rectangular Water Bath

- Heating Mantel

- Digital Spectrophotometer

- Haematocrit Centrifuge

- Water Distillation with Metal Heater

- Hand Specimen Leveler Press

- GROSSING TABLE

- COOLING PLATE

- MICROPROCESSOR PH METER

- DIGITAL FLAME PHOTOMETER

- pH/mV/TEMPERATURE TESTER

- DIGITAL PH, CONDUCTIVITY & TEMPERATURE METER

- Radical Auto Karl Fischer Titrimeter

- Stereo Zoom Microscope

- Jewellery Making Microscope

- Binocular Stereo Microscope

- Advanced Stereo Zoom Microscope

- Articulated Trinocular Stereo Zoom Microscope

- Digital 3D Inspection Microscope

- Binocular Stereo Microscopes

- Motorized Stereo Microscopes

- Trinocular Microscope

- Stereo Inspection Microscope

- Stereo Microscope

- Digital 3D Inspection Microscope RSZ-3D

- Stereo Zoom Microscope RSM-8

- Polarising Microscopes

- Lab Consumables

- Profile Projector

- Optical Profile Projector

- Vertical Profile Projector

- Profile Projector RPP-500

- Profile Projector

- PROFILE PROJECTOR

- Universal Profile Projector

- Bench Type Profile Projector

- Charpy Profile Projector

- High Sharpness Profile Projector

- Profile Projector

- Horizontal Profile Projector

- Digital Profile Projector

- Radical Profile Projector

- Coaxial Profile Projector

- Anotomy Model

- Metallurgical Microscope

- Microscope

- Contact Us

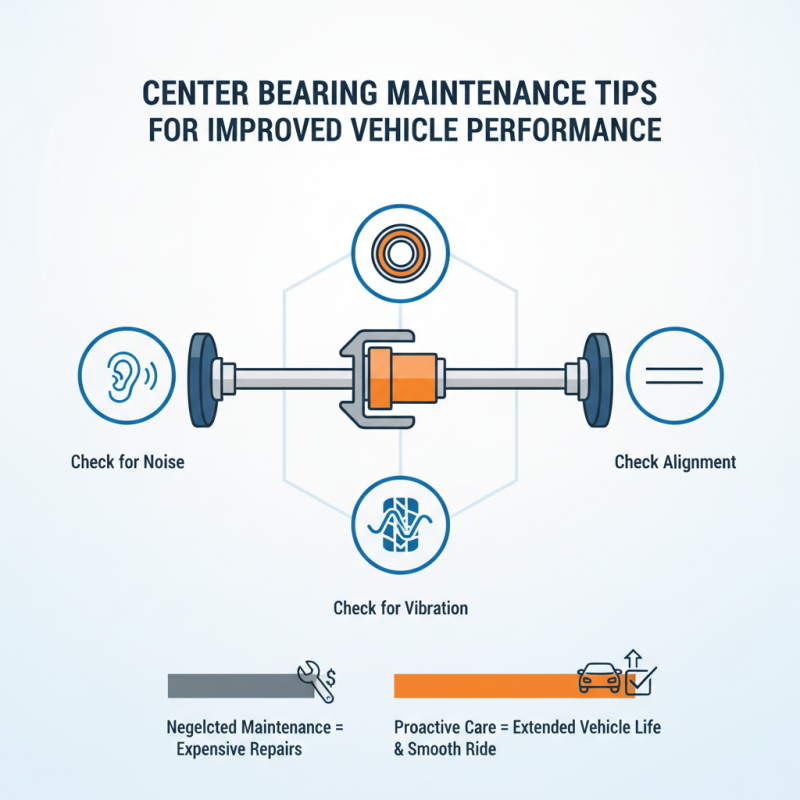

Center Bearing Maintenance Tips for Improved Vehicle Performance?

Maintaining your vehicle's Center Bearing is crucial for optimal performance. Many drivers underestimate its importance. According to a report by the Automotive Maintenance Association, nearly 30% of vehicle vibration issues stem from faulty or neglected Center Bearings. This component plays a vital role in supporting the drive shaft and ensuring a smooth ride.

Expert technician Howard R. Simmons states, “Regular inspection and maintenance of the Center Bearing can prevent bigger issues.” Ignoring this simple task often leads to expensive repairs down the line. For instance, a worn Center Bearing can cause premature failure of the entire drivetrain system. This means that drivers might face not only replacement costs but also downtime in vehicle performance.

Detail-oriented maintenance is important. Drivers should check for noise, vibration, and alignment issues. These are early indicators of a failing Center Bearing. Reflecting on past experiences, many vehicle owners realize they could have saved money with proactive care. Proper Center Bearing maintenance is key to extending vehicle life and improving performance.

Table of Contents [Hide]

Understanding the Role of Center Bearings in Vehicle Dynamics

Center bearings play a crucial role in vehicle dynamics. They support the drive shaft and ensure smooth transitions between different vehicle components. A solid center bearing reduces vibrations, enhancing overall comfort and performance. According to a recent industry report, a functioning center bearing can improve vehicle stability by up to 30%. This is vital for both safety and efficiency.

Neglecting center bearing maintenance can lead to serious issues. A worn center bearing can cause misalignment of the drive shaft. This misalignment can lead to uneven tire wear and might reduce fuel efficiency by up to 15%. Regular checks are necessary but often overlooked. Many vehicle owners assume that if the car runs, everything is fine. This assumption can be costly in the long run.

Many drivers may not recognize the signs of a failing center bearing. Unusual noises, vibrations, and handling issues can indicate potential problems. Addressing these signs early can save time and expenses. Research suggests that proactive maintenance may extend component life by 20-30%. Vehicle efficiency depends on these small parts performing optimally. Ensuring your center bearing works well can significantly enhance driving experience.

Center Bearing Maintenance Tips for Improved Vehicle Performance

| Tip | Description | Frequency | Benefits |

|---|---|---|---|

| Inspect for Wear | Regularly check the center bearings for signs of wear or damage to prevent failures. | Every 6 months | Prevents unexpected breakdowns and enhances safety. |

| Lubricate Bearings | Ensure bearings are properly lubricated to reduce friction and wear. | Every 12 months | Improves longevity and performance of the drivetrain. |

| Check Alignment | Ensure that the center bearings are properly aligned with the drivetrain components. | As needed | Enhances vehicle handling and reduces vibrations. |

| Replace Worn Components | Immediately replace any damaged or excessively worn bearings. | As required | Ensures optimal performance and prevents drivetrain failure. |

| Monitor Vibration | Keep an eye out for unusual vibrations or noises that may indicate bearing issues. | Continuous | Early detection of problems can save costs and improve comfort. |

Signs of Wear and Tear in Center Bearings: What to Look For

Center bearings play a crucial role in vehicle performance. They support the driveshaft and help reduce vibrations. However, wear and tear can occur over time. It's important to know the signs indicating a potential issue. Look out for unusual noises, such as clunking or grinding sounds, while driving. These sounds often signal problems with the center bearings.

Another sign to notice is vibrations. If you feel excessive vibration in the steering wheel or through the chassis, it may be due to worn bearings. Additionally, inspect for visible wear. Check for cracks, rust, or any misalignment in the bearings. These are clear indicators that maintenance is needed.

Regular maintenance is vital. Keep the bearings lubricated to prevent premature wear. Monitor your vehicle’s performance and get a professional inspection if you notice any issues. A little attention now can save you from costly repairs down the road. Remember, every vehicle deserves care and timely intervention.

Recommended Inspection and Maintenance Intervals for Optimal Performance

Regular inspection and maintenance of the center bearing is crucial for your vehicle's performance. These components help support the driveshaft, and if they wear down, you may face vibrations or noise during operation. It's important to check these bearings every 30,000 miles or when you notice any symptoms of wear. Look for signs like uneven wear or rust, as these can indicate underlying issues.

In addition to scheduled checks, drivers should pay attention to the condition of rubber bushings attached to the bearings. Cracks or fraying can compromise performance. Replacing worn or damaged bushings can prevent further problems and extend the lifespan of your vehicle's drive system. Keeping an eye on these components encourages smooth operation and can save on costly repairs.

Inspecting and maintaining center bearings requires commitment. Some may overlook these checks, thinking they are unnecessary. However, a little diligence goes a long way in ensuring optimal performance. Regular maintenance can catch small issues before they become significant, ensuring your vehicle remains reliable on the road.

Impact of Proper Center Bearing Maintenance on Fuel Efficiency

Proper maintenance of the center bearing is crucial for vehicle performance. Neglecting this component can lead to increased vibrations and noise. These issues often go unnoticed until they become significant problems. A well-maintained center bearing contributes to smoother rides. This improvement also positively influences fuel efficiency.

Fuel efficiency can suffer when the center bearing is worn. A failing bearing creates more drag on the driveshaft. This additional resistance causes the engine to work harder, consuming more fuel in the process. Regular inspection and lubrication can mitigate these effects. However, it is easy to overlook such maintenance tasks, especially during busy schedules.

Many drivers may not realize the connection between bearing condition and fuel efficiency. Some vehicle owners think it's just an inconvenience, not a serious concern. Ignoring these signs can lead to costly repairs later on. A proactive approach can save money and improve overall vehicle performance. Regular maintenance checks are essential for long-term efficiency.

Tools and Techniques for Effective Center Bearing Replacement and Repair

When it comes to center bearing maintenance, using the right tools is essential. A quality socket set can make the job easier. Consider investing in a torque wrench to ensure proper tightness. A hammer might be necessary too, but avoid heavy strikes; it can damage components. Keeping a clean workspace is crucial for effective repairs.

During the replacement process, inspect the old bearing closely. Look for signs of wear, like cracks or excessive rust. Take your time removing the old parts; impatience can lead to additional issues. Aligning the new bearing correctly is important for optimal vehicle performance. A misalignment can cause vibrations and headaches later. Don't rush this step.

After installation, test drive your vehicle at low speeds. Listen for unusual noises that could indicate an issue. If something feels off, revisit your work. It’s always good to double-check. This attention to detail can save you time and prevent future repairs. Regular maintenance checks can help prolong the life of the center bearing, ensuring smoother rides ahead.

Article Source:

Contact Us

- 9th Milestome, Ambala-Jagadhri Road, P.O.- Khudda Kalan, NH-444A,Ambala Cantt - 133104, Haryana, India

- Phone : 08045479132

- Mrs POONAM BHANDARI (Incharge - Mktg & Sales )

- Mobile : 08045479132

- Send Inquiry

GST : 06AACCR8985N1ZI

Our Products

RADICAL SCIENTIFIC EQUIPMENTS PVT. LTD.

All Rights Reserved.(Terms of Use)

Developed and Managed by Infocom Network Private Limited.

Developed and Managed by Infocom Network Private Limited.