- Home Page

- Company Profile

-

Our Products

- Microscope

- CONFOCAL MICROSCOPES

- Trinocular Upright Metallurgical Microscope

- Portable Grooved Metallurgical Microscope

- Cell Culture Imaging System

- Metallurgical Microscope

- Projection Microscope

- Student Stereo Microscope

- BINOCULAR STEREO ZOOM MICROSCOPE

- PCB Inspection Video Stereoscope Microscope

- SPINNERET MICROSCOPE

- Penta Head Microscope/ Multi view Head Microscope

- Research Polarising Microscope

- Senior Dissecting Microscope

- Dissecting Microscope

- Motorized Comparision Microscope

- Sieves Digital Microscopes

- Advance Inverted Tissue Culture Microscope

- Advance Stereo Zoom Microscope

- Student Projection Microscope

- Inverted Metallurgical Microscope

- Measuring Microscope

- Digital Spinneret Inspection Microscope

- Portable Inverted Tissue Culture Microscope

- Binocular Inverted Tissue Culture Microscope

- Student Compound Microscope

- Trinocular Stereozoom Microscope

- Advanced Research Microscope

- Gemological Microscope

- Polarizing Projection Microscope

- Senior Inspection Spinneretscope

- Confocal Microscope

- Senior Projection Microscope

- Toolmaker's Microscope

- Research Microscope

- Stereo Inspection Microscope

- Student Medical Microscope

- Digital Biological Microscope RXLr-4D

- Toolmaker Microscope Large

- Stereo Inspection Scope

- Trinocular Research Microscope

- Portable Metallurgical Microscope

- Binocular Research Microscope

- Student School Microscope

- Inverted Tissue Culture Microscope

- Projection Microscope

- Laboratory Microscope

- Decca Head Microscope

- Advanced Research Material Microscope

- Microtomes

- Semi Automatic Rotary Microtome

- Senior Precision Rotary Microtome

- Rocking Microtome

- Rotary Microtome Erma Type

- Freezing Microtome

- Fully Automatic Rotary Microtome

- Manual Rotary Microtome RMT-25

- Advance Rotary Microtome

- Hand Table Microtome

- Knife Sharpener Microtome

- Sliding Miocrotome

- Slide Staining Machine

- Rotary Microtome

- CRYOSTAT MICROTOME

- Optical Instruments

- Tissue Processor Machine

- Microscope Accessories

- Histopathological Equipment

- Lab Instrument

- Radical Digital Turbidity Meter

- Radical Microprocessor Dissolved Oxygen Meter

- Digital Photo Colorimeter

- Tap Density Tester

- Serological Water Bath

- Magnetic Stirrer

- Dual Channel Flame Photometer

- pH or mv or Conductivity

- Round Centrifuge

- Radical Disintegration Test Apparatus

- Digital Slide Scanner

- Precision Water Bath

- Incubator Shaker Water Bath

- Hemoglobin meter

- Microprocessor Colony Counter

- PASS BOX DYNAMIC

- Radical Microprocessor Colony Counter

- Bulk Density Apparatus

- Laboratory Rectangular Hot Plates

- Tablet Dissolution Test Apparatus

- Hemoglobin Meter (Sahli's)

- Micro Centrifuge 16000 R.P.M.

- Revolutionary General Purpose Digital Centrifuge

- Vortex Shaker

- Rectangular Water Bath

- Heating Mantel

- Digital Spectrophotometer

- Haematocrit Centrifuge

- Water Distillation with Metal Heater

- Hand Specimen Leveler Press

- GROSSING TABLE

- COOLING PLATE

- MICROPROCESSOR PH METER

- DIGITAL FLAME PHOTOMETER

- pH/mV/TEMPERATURE TESTER

- DIGITAL PH, CONDUCTIVITY & TEMPERATURE METER

- Radical Auto Karl Fischer Titrimeter

- Stereo Zoom Microscope

- Jewellery Making Microscope

- Binocular Stereo Microscope

- Advanced Stereo Zoom Microscope

- Articulated Trinocular Stereo Zoom Microscope

- Digital 3D Inspection Microscope

- Binocular Stereo Microscopes

- Motorized Stereo Microscopes

- Trinocular Microscope

- Stereo Inspection Microscope

- Stereo Microscope

- Digital 3D Inspection Microscope RSZ-3D

- Stereo Zoom Microscope RSM-8

- Polarising Microscopes

- Lab Consumables

- Profile Projector

- Optical Profile Projector

- Vertical Profile Projector

- Profile Projector RPP-500

- Profile Projector

- PROFILE PROJECTOR

- Universal Profile Projector

- Bench Type Profile Projector

- Charpy Profile Projector

- High Sharpness Profile Projector

- Profile Projector

- Horizontal Profile Projector

- Digital Profile Projector

- Radical Profile Projector

- Coaxial Profile Projector

- Anotomy Model

- Metallurgical Microscope

- Microscope

- Contact Us

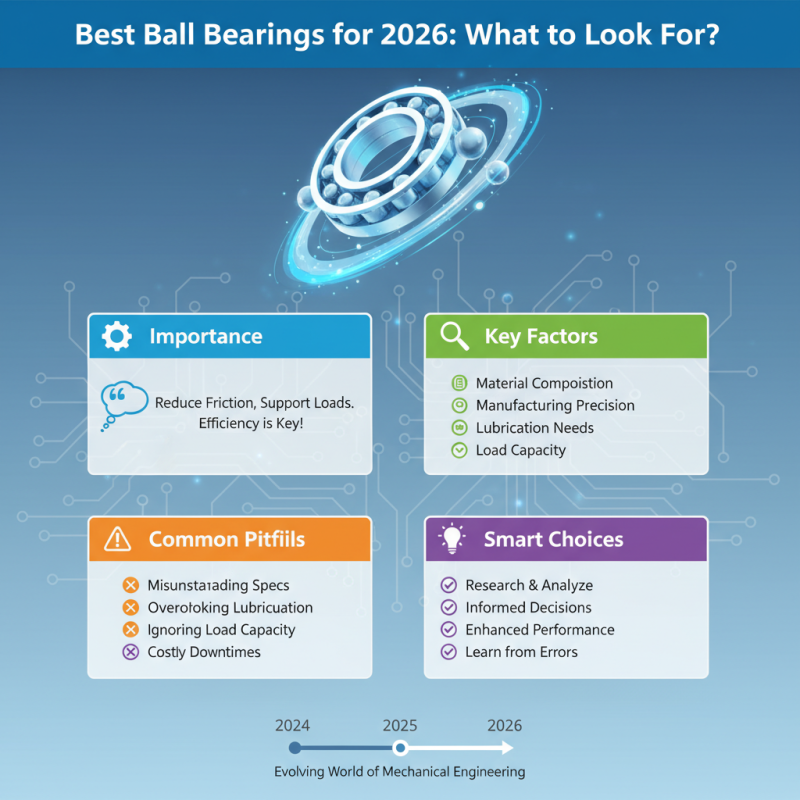

Best Ball Bearings for 2026 What to Look For?

In the evolving world of mechanical engineering, the significance of high-quality Ball Bearings cannot be overlooked. John Thompson, a renowned expert in the field, once said, "The right Ball Bearing can determine a machine's efficiency." As industries innovate, selecting the best Ball Bearings for 2026 will be crucial.

Understanding Ball Bearings is essential, as they reduce friction and support loads. In today’s market, the variety is overwhelming. Many factors play a role in their performance. From material composition to manufacturing precision, small details can greatly impact outcomes.

However, it’s not always easy to choose the right option. Misunderstandings about specifications often lead to poor decisions. Companies might overlook critical characteristics, like lubrication needs or load capacity. This can result in costly downtimes. By researching and pinpointing what to look for, we can make informed choices that enhance machinery performance while learning from past errors.

Table of Contents [Hide]

Key Factors to Consider When Choosing Ball Bearings for 2026

Choosing the right ball bearings in 2026 involves several important factors. First, consider the material. Bearings are often made from steel, ceramic, or plastic. Each material has its benefits and drawbacks. Steel is durable but heavy. Ceramic is lightweight, but can be fragile.

Next, think about the size and load rating. A bearing must fit well within your application. Check the size specifications. Too large or too small can lead to inefficiency. Load rating matters too. You want a bearing that can handle your equipment's weight and stress.

Finally, consider the operating conditions. Temperature, humidity, and exposure to contaminants all affect performance. High temperatures can lead to faster wear. On the other hand, certain lubricants may not work well in all environments. Think critically about your needs and possible challenges. Not all bearings will perform as expected. Trial and error may be necessary.

Types of Ball Bearings: Understanding the Options Available

When selecting the best ball bearings for 2026, understanding the various types is crucial. There are several common options. Deep groove ball bearings are versatile and widely used. They can handle radial and axial loads. Angular contact ball bearings excel in high-speed applications. They support angular loads effectively.

Ceramic ball bearings offer unique benefits. They are lighter and resist corrosion. However, they can be more expensive. Choosing the right type depends on your specific needs. Consider the environment and load requirements.

Tips: Always examine weight limits for your application. Testing different bearings can provide insights. Don’t overlook noise levels; a quieter bearing often means better performance. Balancing cost and quality is key. Make sure to review specifications carefully, as not all bearings are created equal.

Material Choices: Which Materials Enhance Bearing Performance?

When selecting ball bearings for optimal performance, material choices play a critical role. Steel bearings are traditional. They offer durability but may rust if exposed to moisture. In contrast, ceramic materials are lighter and provide better resistance to heat and corrosion. According to a report by the International Journal of Engineering, ceramic ball bearings can outperform steel by up to 40% in terms of life expectancy under similar conditions.

However, not all materials are equally functional in every situation. Composite materials can fill the gap where both steel and ceramic fall short. They can absorb shock and vibration, making them suitable for many applications. Yet, they might not withstand extreme temperatures. Balancing material properties with operational needs is essential.

Further considerations include the level of lubrication required by different materials. For example, while ceramic bearings need minimal lubrication, steel requires regular maintenance. Neglecting lubrication standards can lead to premature failure. As 2026 approaches, understanding the nuances of material choices is imperative. Ultimately, the aim is to optimize performance while addressing potential weaknesses.

Load Ratings and Their Importance in Bearing Selection

When selecting the best ball bearings for 2026, load ratings are crucial. They provide insights into how much weight a bearing can handle. Understanding these ratings can prevent unexpected failures in machinery. Each application has different requirements, so there is no one-size-fits-all solution.

In general, higher load ratings mean better performance. However, this doesn't always guarantee longevity. Factors like speed, temperature, and environment also matter. Sometimes, a bearing with a lower rating performs better in specific conditions. Users must assess their unique situations carefully.

Relying solely on load ratings could lead to mistakes. It's essential to consider other variables. Think about the specific application and real-world conditions. This reflection can lead to better choices. After all, the right bearing not only enhances efficiency but also minimizes maintenance. Understanding load ratings is just the beginning of a more complex selection process.

Trends in Ball Bearing Technology for the Year 2026

In 2026, ball bearing technology will likely experience significant advancements. New materials are expected to enhance performance. For example, ceramic composites could reduce friction and increase durability. This leads to longer lifespan and better efficiency. Enhanced lubrication systems will also play a crucial role. They can provide better protection under extreme conditions.

Innovative designs might emerge, focusing on weight reduction. Lighter ball bearings can improve speed and energy consumption. Smoothness in motion will be prioritized. Customization options may grow as well. Users might want specific dimensions for unique applications. However, these developments come with challenges. Implementing new techniques could be costly. Traditional manufacturers may struggle to adapt. Quality control is vital as innovations are tested.

Understanding user needs will remain essential. Feedback loops can guide engineers in refining designs. Collaboration with industries will help tailor solutions. As technology evolves, some aspects might fall short. Yet, progress often hinges on these early stumbles. Balancing innovation and reliability is key for manufacturers in 2026.

Article Source:

Contact Us

- 9th Milestome, Ambala-Jagadhri Road, P.O.- Khudda Kalan, NH-444A,Ambala Cantt - 133104, Haryana, India

- Phone : 08045479132

- Mrs POONAM BHANDARI (Incharge - Mktg & Sales )

- Mobile : 08045479132

- Send Inquiry

GST : 06AACCR8985N1ZI

Our Products

RADICAL SCIENTIFIC EQUIPMENTS PVT. LTD.

All Rights Reserved.(Terms of Use)

Developed and Managed by Infocom Network Private Limited.

Developed and Managed by Infocom Network Private Limited.